1. Description

| Size | 10ml 30ml 50ml 120ml 30g 50g 100g |

| OEM | We can make new molds as required |

| Use | Lotion bottle,cream jar etc |

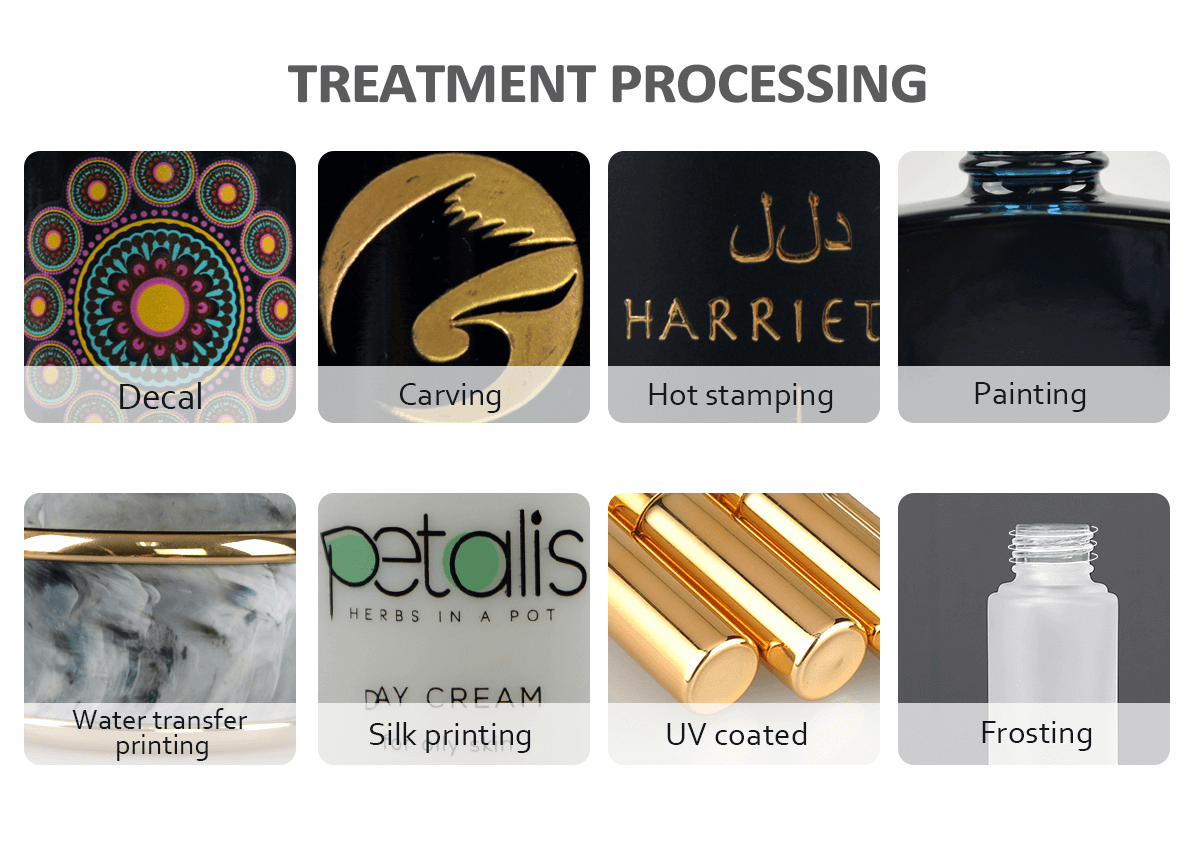

| Logo printing | Available |

| MOQ | 10000pcs/size |

| Packing | Carton with grid inside and pallet is available |

| Payment | 30%T/T prepaid,the balance before delivery |

| Delivery | Within 45days after down payment and samples’ approval |

| Our service | Available to customize the items according to your sample& design or OEM& ODM. Printing your logo on the box or engraving any image with the product are also warmly welcome. |

| Samples policy | If you give quick enquiry, 5 free samples are available.The express freight charges should be on buyer's account. |

| Silk printing,UV coated,Hot stamping,frosted,painting etc can be available. | |

2. Feature of Product

1.Uzone's glass bottles are widely used in the personal care industry.

2.Different size,volumes,style,color of glass bottles are available

3.Customer designs available.

4.Samples are available at our existing shape.

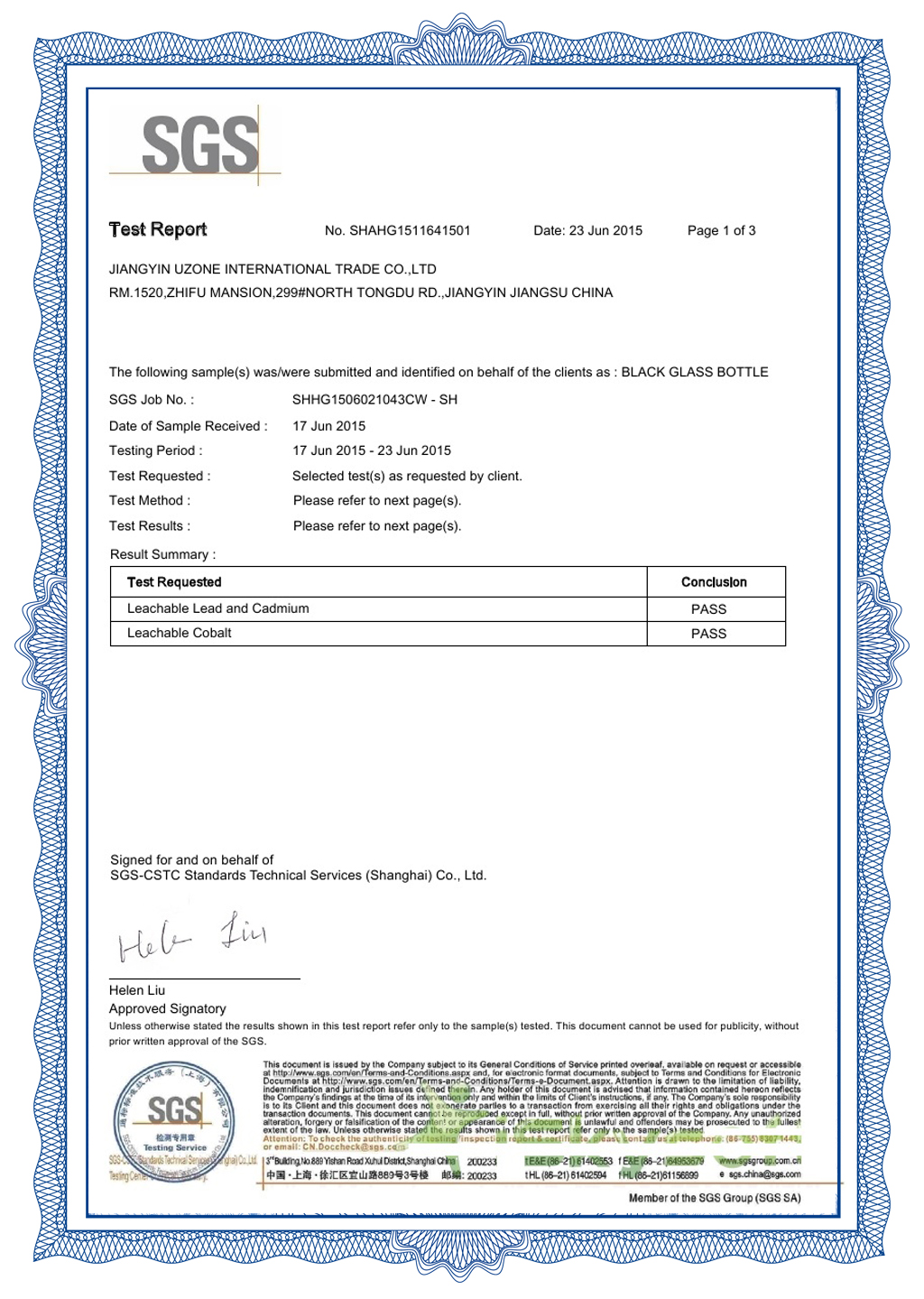

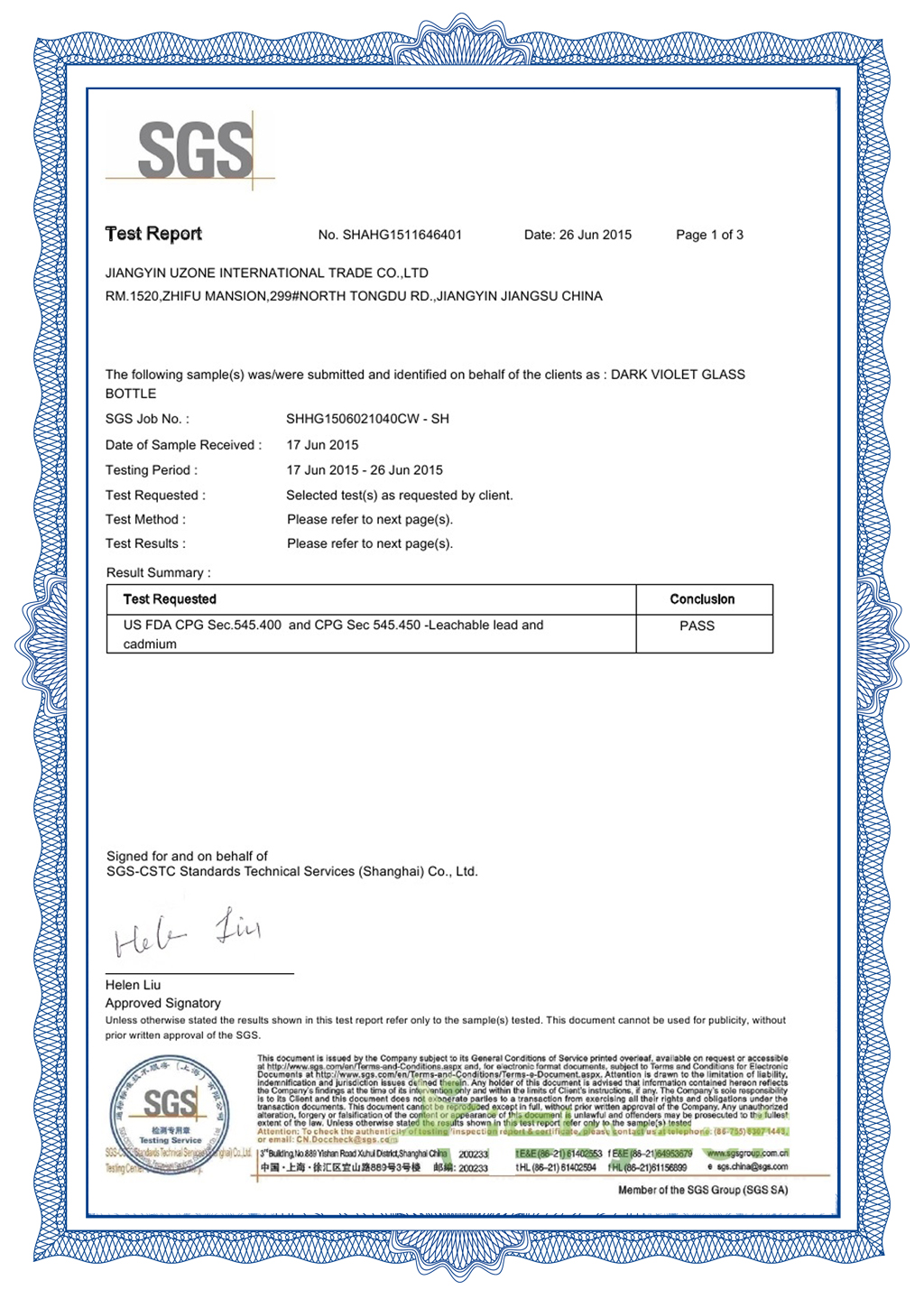

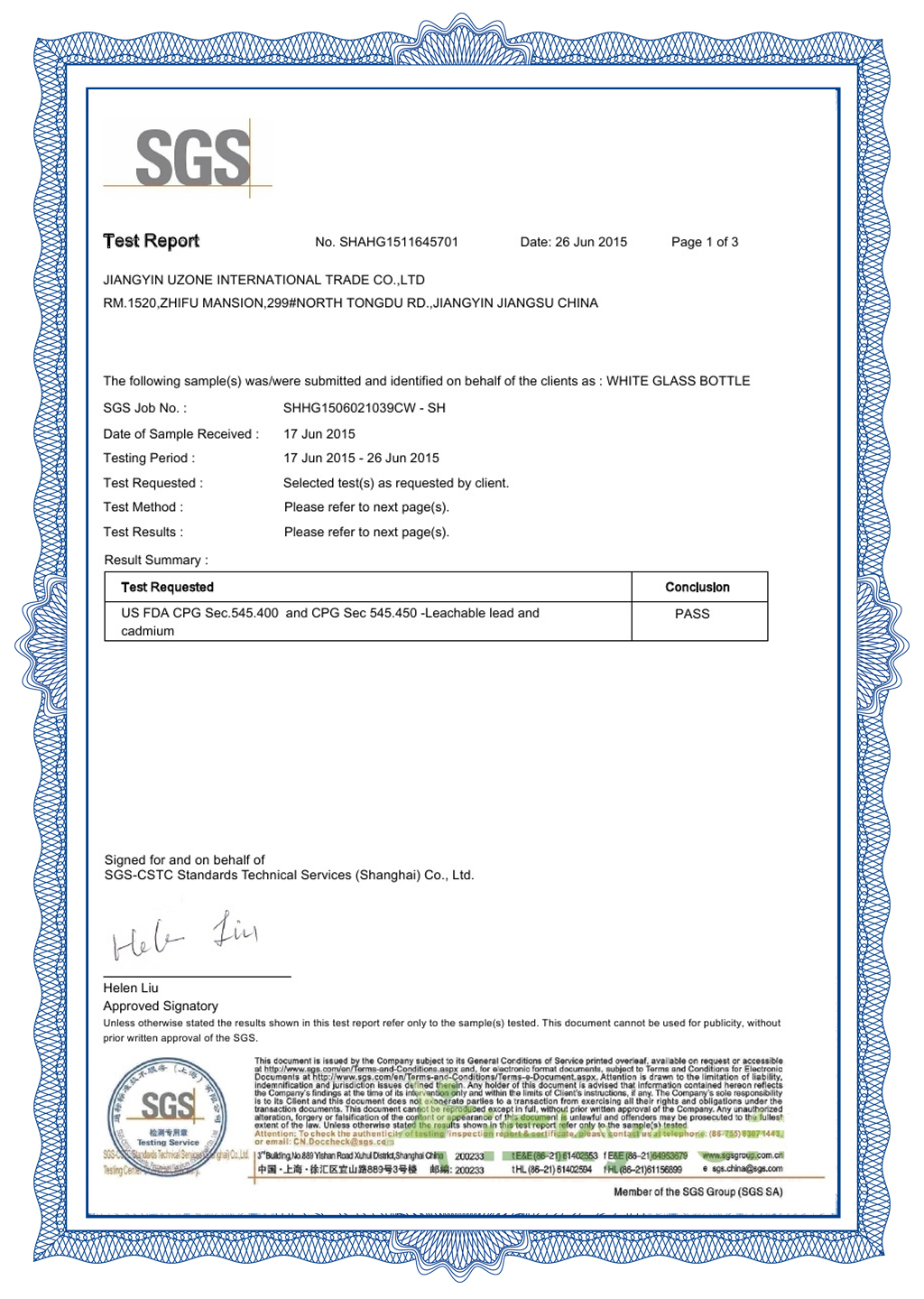

5.Conform with USA,Europe Stand

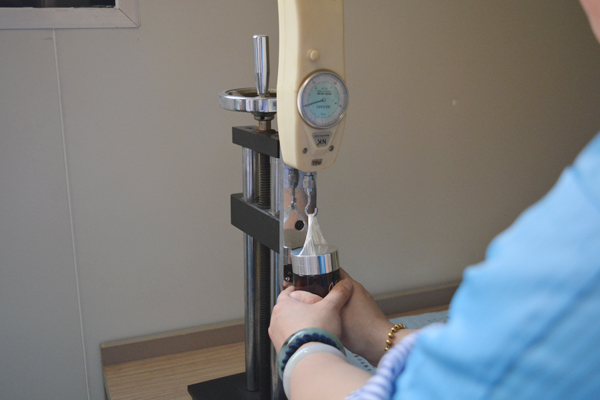

Patrol inspection of production line, full inspection of packing, full inspection before leaving factory to ensure the quality of products delivered to customers.

Full set of testing equipment, professional inspection knowledge training, to ensure the professionalism of all quality inspection personnel.

With the development of the glass bottle product industry, the glass factory will gradually develop into a group production model, forming a large-scale production capacity. Several benefits of using glass bottles:

1. Low cost. Plastic bottles account for about 20% of the production cost in the product (commodity) price composition, while glass bottles are extremely low in terms of production or recycling costs, accounting for about 3 to 5% of the product (commodity) price composition Therefore, glass bottles instead of plastic bottles are the most economical way.

2. Good chemical stability. The glass bottle has good chemical stability and durability, safety and sanitation, good corrosion resistance and acid corrosion resistance.

-

Opal White Glass Bottle And Jar With Bamboo/Rub...

-

Refillable Roll on 10ml Transparent perfume Ess...

-

150ml Glass Reed Diffuser Bottle With Wooden Plug

-

PET Plastic Bottle And Jar With Bamboo/Rubber W...

-

15g 30g 50g 100g frosted glass jar with bamboo lid

-

15ml 30ml 50ml 80ml 100ml 120ml 150ml dark viol...