Many friends have this question above, and there is always a choice to make. People love the violet glass,but the price seems quite high and the products do not have enough stocks. When they come to Chinese market, quality control is another problem.

This article may give you an idea that you can have another choice.

Appearance

Violet glass can present the beautiful violet color under strong light although it looks exactly the same as the opaque black glass in the appearance. The violet color is due to the manganese in the raw material of the glass. During the producing, the color can also be different when the dose of manganese changes. It all depends to the experience of the engineer.

For the opaque black glass, color seems much easier to be managed. The good thing is that the black color is more uniform.

Dark violet glass under sunlight Opaque black glass under sunlight

Performance

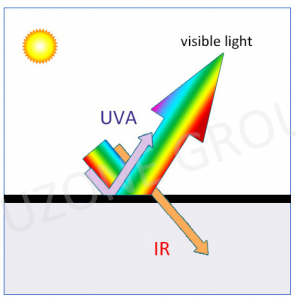

Opaque Black glass is very good at UV-proof.

It performs even better than the dark violet glass which is well known as UV biophotonic glass.

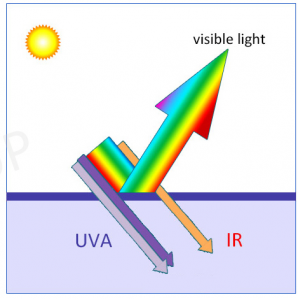

Violet glass can reflect the visible light but not the UVA and infrared radiation, while the opaque black glass can reject the harmful UVA, that is quite important to the skin care and cosmetic products.

As you all know that the harmful sunlight like UVA is the main reason to the biological aging, so the less UVA is taken in, the longer the ingredients will keep fresh. When you consider this point, the opaque black glass becomes a more wise choice for storing the substances that oxidize easily.

Violet glass Opaque black glass

Manufacture condition

Before the mass producing, a product mold is necessary. In China, no auto-machine mold is available for violet glass production at present, so all the violet glass are made by hand.

But the opaque black glass is made by machine, thus you will find many differences between them as below:

https://www.youtube.com/watch?v=LuD9h8xNAeg (Auto machine factory)

https://www.youtube.com/watch?v=BmxU_OKTgdE (Hand made work shop)

Quality

The very fragile neck may break when you screw the lid on, the bottle body is hardly shaped, there are more bubbles and cracks on the glass because of the temperature change in the oven. These are all about hand made violet glass. On the contrary, you hardly find these problems among the machine made black bottles.

https://www.youtube.com/watch?v=MBdUbPgg2Fs (Controlled trials)

Capacity

Every 2 experienced workers can produce around 200-500 pieces hand made violet glass products, including the unqualified ones. While a standard machine can produce around 100,000-200,000 pieces glass products a day with nice quality. Meaning the leading time for the machine made black glass can be much shorter then the hand made violet glass.

Price

Thanks to the automatic producing technology, the opaque black glass bottle can save around 20-30% cost compared to the violet glass. Except the labor cost, quality control is another reason why the manufacturers have to offer higher quotation. To ensure the customers get the qualified products, they supplier must pick out those ugly glass, that means they need to produce around 20% more glass to meet the order quantity.

Post time: Jun-16-2022